Hollow Blocks

Home » Hollow Blocks

Explore Our

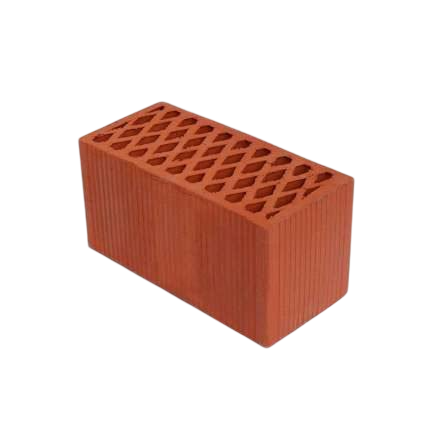

Best Quality Clay Hollow Blocks

Thermobrick® Hollow Blocks are advanced clay hollow block walling solutions designed to deliver superior strength, thermal insulation, and faster construction. Manufactured using state-of-the-art European technology, these blocks are an ideal alternative to conventional bricks and AAC blocks.

Developed by Jindal Mechno Bricks Pvt Ltd, Thermobricks combine durability, sustainability, and cost efficiency, making them suitable for modern residential, commercial, and institutional buildings.

Brick / Tile Calculator

| 4 Inch | 9 Inch | |

|---|---|---|

| Total Required | 0 | 0 |

Types of Thermobrick® Hollow Blocks

Horizontal Hollow Blocks

Horizontally perforated design

Ideal for partition and infill walls

Excellent thermal and sound insulation

Preferred for high-rise construction

Vertical Hollow Blocks

Vertically perforated design

High compressive strength

Suitable for structural walls

Reduces need for RCC columns

Technical specifications

| Product | Size | Weight (kg) | Compressive Strength (KG/CM2) | Water Absorption (%) | Perforation (%) | Efflorescence |

|---|---|---|---|---|---|---|

| Vertical Hollow Block | 280x135x130mm | 5.5 | 100 | <15 | 26 | Negligible |

| Vertical Hollow Block | 280x70x130mm | 2.8 | 100 | <15 | 26 | Negligible |

| Vertical Hollow Block | 280x205x130mm | 8.3 | 100 | <15 | 26 | Negligible |

| Horizontal Hollow Block | 100x200x400mm | 7.8 | 35 | <15 | >45 | Negligible |

| Horizontal Hollow Block | 150x200x400mm | 11.5 | 35 | <15 | >45 | Negligible |

| Horizontal Hollow Block | 200x200x400mm | 12.4 | 35 | <15 | >45 | Negligible |

Construction site images

affordable housing project, Madhya Pradesh

Features and Benefits of Hollow Blocks

Faster Construction

Large block size replaces multiple traditional bricks, reducing joints and speeding up wall construction, resulting in quicker project completion.

Lightweight yet Strong

Up to 60% lighter than conventional bricks while maintaining high compressive strength, reducing overall structural load on the building.

Superior Thermal Insulation

Hollow cavities provide excellent thermal insulation, helping maintain comfortable indoor temperatures and reducing cooling and heating costs.

Enhanced Sound Insulation

The perforated clay structure minimizes sound transmission, making Thermobrick® Hollow Blocks ideal for residential and commercial buildings.

Cost-Effective Construction

Lower mortar consumption, reduced plastering requirements, and minimal maintenance lead to significant savings in construction costs.

Sustainable & Eco-Friendly

Manufactured using energy-efficient processes with low water absorption and minimal efflorescence, supporting green and sustainable construction practices.

SUPERIORITY

Why Choose Us for Hollow Blocks

Strict Quality Control

From raw material testing to final inspection, every block undergoes systematic quality checks to meet high performance standards.

Advanced European Technology

Our hollow blocks are produced using state-of-the-art European machines, ensuring consistent quality, strength, and dimensional accuracy.

Trusted by Builders

Architects, engineers, and contractors rely on our hollow blocks for their durability, reliability, and consistent quality and long-term performance.

Strong and Durable

Jindal Mechno Bricks' Hollow Blocks are designed to withstand the test of time, ensuring long-lasting performance and minimal maintenance.

Manufacturing Expertise

With experience dating back to 1972, we bring proven knowledge, industry expertise, superior quality standards, and precision to every hollow block we manufacture.

Customer Support

We provide excellent customer support, assisting clients in choosing the right face bricks for their projects and offering guidance throughout the process.

Jindal Mechno Bricks Best Building Materials Provider in India

Jindal Mechno Bricks stands as the famous building materials provider in India, setting the standard for quality and trustworthiness in the industry. With a wide array of top-notch products, including face bricks, extruded bricks, and exposed bricks, their offerings cater to diverse construction needs.

Backed by years of experience, the company ensures each material meets stringent quality checks, guaranteeing durability and performance. From sustainable manufacturing practices to a strong commitment to customer satisfaction, Jindal Mechno Bricks is the preferred choice for architects, builders, and developers nationwide.

| Benefit | Description |

|---|---|

| Lightweight Construction | Hollow blocks are significantly lighter than conventional solid bricks, reducing dead load on the structure and lowering overall construction costs. |

| High Structural Strength | Despite being lightweight, hollow blocks offer high compressive strength, making them suitable for both load-bearing and non-load-bearing walls. |

| Thermal Insulation | The hollow cavities provide excellent thermal insulation, helping maintain comfortable indoor temperatures and improving energy efficiency. |

| Sound Insulation | Hollow block walls reduce sound transmission, enhancing acoustic comfort in residential, commercial, and institutional buildings. |

| Faster Construction | Larger block size and uniform shape reduce mortar joints, enabling faster construction and quicker project completion. |

| Cost & Eco Efficiency | Lower mortar, plaster, and water consumption combined with sustainable manufacturing makes hollow blocks an economical and eco-friendly building solution. |

Why choose Jindal Mechno Bricks Pvt Ltd hollow blocks?

- With manufacturing experience dating back to 1972, Jindal Mechno Bricks Pvt Ltd produces hollow blocks using advanced European technology, ensuring consistent quality, strength, and long-term performance trusted by builders and professionals.

Are Jindal hollow blocks suitable for load-bearing construction?

- Yes, our hollow blocks are engineered to offer high compressive strength and are suitable for both load-bearing and non-load-bearing walls when used as per structural guidelines.

Do Jindal hollow blocks help reduce construction costs?

- Absolutely. Our hollow blocks reduce dead load, require less mortar and plaster, and enable faster construction, resulting in significant overall cost savings.

Can Jindal hollow blocks be used in high-rise buildings?

- Yes, our hollow blocks are widely used in multi-storey and high-rise projects, offering reduced structural load, improved insulation, and reliable performance when used as per approved designs.