Bricks are the building blocks of a structure which provide it strength, durability, and aesthetic appeal. But with many brick types available, choosing the right one for your project requires careful consideration of factors like composition, strength, aesthetics, and budget. Each type of brick has its own set of benefits, making them suitable for different aspects of construction. Whether you are building a home, commercial space, or landscape project, there is a brick type that meets your needs. This guide aims to simplify that choice, helping you understand the various types of bricks in India and how to pick the best one for your needs, ensuring your construction is not just a building but a lasting legacy. Let’s explore how to pick the perfect brick.

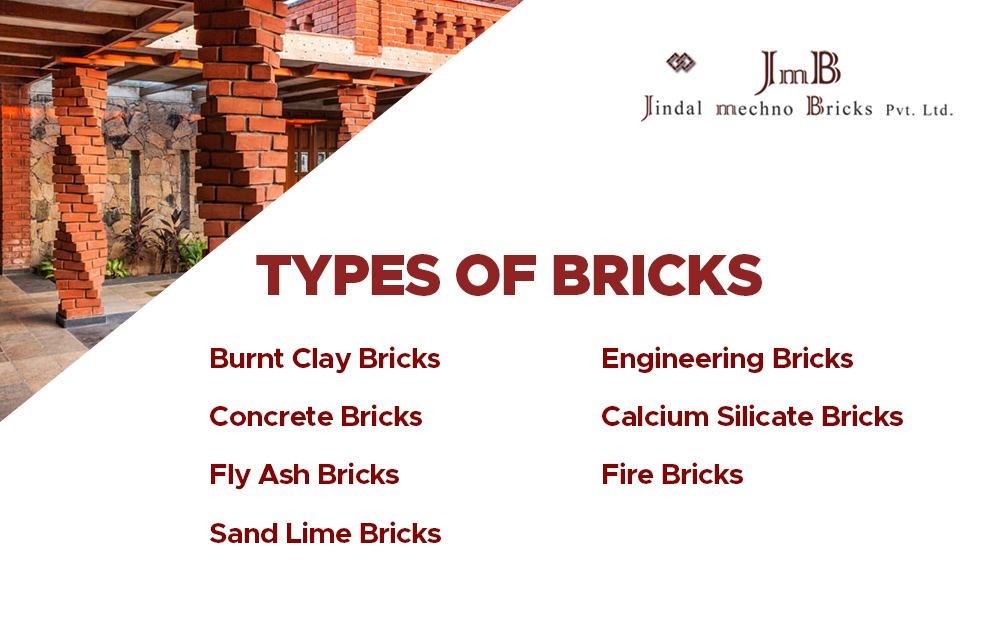

Different Types of Bricks

Bricks, the building blocks of countless structures, come in various types, each with unique qualities and uses. Let’s explore some most common types of bricks in India:

Burnt Clay Bricks: These are the classic bricks that come to mind for most construction projects. After shaping clay into moulds, we fire them in a kiln to make them hard and strong. Perfect for walls that hold up buildings, these bricks are reliable and have been used for centuries. There are four classes of burnt clay bricks, with Class 1 being the highest quality, offering the best strength and durability for major construction work.

Concrete Bricks: Think of concrete bricks as the versatile cousin of traditional bricks. We make them by pouring concrete into moulds and letting it set. You can find these bricks in various colours, making them great for decorative walls or facades. They’re not just pretty; they’re also tough and can be used for structural parts of buildings.

Fly Ash Bricks: These are the eco-friendly heroes of the brick world. Made from fly ash (a byproduct of burning coal), water, and sand, these bricks are not only good for the planet but also light and strong. They are great insulators, keeping buildings cooler in summer and warmer in winter. Plus, they are uniform in size, making construction quicker and smoother.

Sand Lime Bricks: Also known as calcium silicate bricks, these are made by mixing sand, lime, and fly ash under high pressure and steam curing. The result? Bricks with a smooth finish and a slightly grey colour offer a modern look for buildings. They’re strong, with good acoustic insulation, making them ideal for both structural and aesthetic purposes.

Engineering Bricks: These bricks are known for their exceptional strength and water resistance. Engineering bricks are made to perform under harsh conditions, making them perfect for projects that require extra durability, such as foundations, sewers, and retaining walls. They come in two classes: Class A and Class B, with Class A offering the highest level of water resistance. If your construction needs a brick that can withstand the elements and bear heavy loads, engineering bricks are the way to go.

Calcium Silicate Bricks: Often confused with sand lime bricks due to their similar manufacturing process, calcium silicate bricks stand out for their wide range of colours and smooth texture. These bricks are made by mixing sand and lime and then pressing the mixture into moulds. The bricks are then cured using steam in an autoclave, which enhances their strength and durability. Ideal for both structural and decorative uses, calcium silicate bricks offer a modern and aesthetically pleasing option for buildings that require a sleek, contemporary look.

Fire Bricks: Also known as refractory bricks, fire bricks are designed to stand up to extremely high temperatures. Made from fire clay, which can withstand the intense heat of a kiln or a furnace, these bricks are essential for lining fireplaces, chimneys, and pizza ovens. Their ability to retain heat makes them an excellent choice for projects that involve high temperatures, ensuring safety and efficiency. Fire bricks come in various shapes and sizes, tailored to fit specific heating applications, making them a crucial component for any construction that deals with fire and heat.

How to Select the Best Brick

Selecting the right brick involves considering several factors:

Purpose of Construction: The choice of brick largely depends on the type of construction project. For load-bearing structures, burnt clay bricks are preferred for their strength. For aesthetic purposes, sand lime or concrete bricks might be more appropriate.

Climate: The local climate plays a crucial role in brick selection. For areas prone to heavy rainfall, bricks with low water absorption, such as fly ash bricks, are advisable.

Sustainability: If environmental impact is a concern, opting for eco-friendly bricks like fly ash bricks can contribute to sustainability without compromising on quality.

Budget: While it is important not to compromise on quality, budget constraints can influence your choice. Concrete and fly ash bricks are more cost-effective compared to traditional burnt clay bricks.

Aesthetic Preference: The appearance of the brick is also a key consideration. Concrete and sand lime bricks offer a range of colours and finishes, allowing for more creative freedom in design.

Conclusion

Choosing the right brick is a decision that shapes the future of your construction. By understanding the types of bricks in India available and considering the factors crucial to your project, you can make an informed decision that aligns with your vision. At Jindal Mechno Bricks, we pride ourselves on being more than just a brick manufacturer; we are your partners in building dreams. Our expertise, combined with a commitment to quality and sustainability, ensures that we provide the best bricks for home construction tailored to meet the unique demands of your projects. Choose Jindal Mechno Bricks and take the first step towards constructing a legacy that will stand the test of time.

FAQs

How do I choose the right type of brick for my construction project?

Ans. To pick the right brick, think about what you need it for. If you are building something that needs to be really strong and handle lots of weight, like a foundation, go for burnt clay bricks or engineering bricks. If you want your building to look nice and colourful, concrete bricks or calcium silicate bricks might be what you need. And if you are building something that will get very hot, like a fireplace, then fire bricks are the way to go.

Can I use different types of bricks in the same construction project?

Ans. Yes, you can! Different parts of a building might need different kinds of bricks. For example, you might use engineering bricks for the foundations because they are solid and water-resistant, and then use calcium silicate bricks for the walls because they come in different colours and have an excellent finish.

Are eco-friendly bricks like fly ash bricks as strong as traditional bricks?

Ans. Yes, fly ash bricks are pretty strong, and they are great for the environment, too. They are made from waste materials, so using them helps reduce pollution. Plus, they’re good insulators, which can help keep your building cooler in the summer and warmer in the winter.

How often should I check and maintain the bricks in my building?

Ans. It is a good idea to check your bricks at least once a year for any signs of damage, like cracks or chips. If you see any damage, it is important to get it fixed right away to keep your building safe and strong. Regular cleaning and maintenance can also help your bricks last longer and keep your building looking its best.