Company Profile

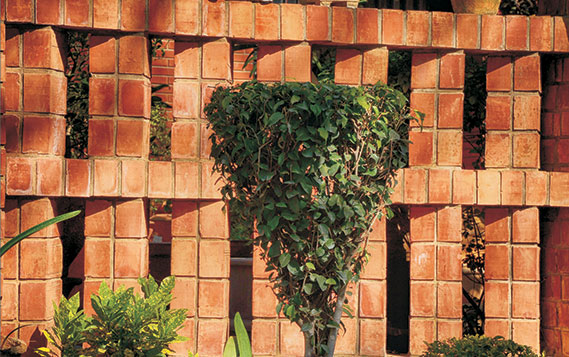

Jindal Mechno Bricks Pvt Ltd is a leading manufacturer of machine made bricks, unglazed ceramic cladding tiles, brick pavers & hollow blocks. After manufacturing handmade bricks since 1972, Jindal Mechno Bricks Pvt Ltd, an IS0 9001 : 2008 certified company, was founded by Late Shri HansRaj Jindal & sons in 1996 to manufacture machine made bricks which are ideal to be left exposed, need not be plastered or painted. Today, bricks and related products are manufactured using both technologies of press and extrusion. We are using the latest European machines & technologies and raw materials are thoroughly tested and processed in a systematic way so that the finished products have the best quality.

With the firing capacity of 150 ton per day, our production capacity & product inventories are sufficient to cater projects requiring large quantities. JMB has catered to many large scale projects. To name a few, we have supplied bricks to the Sharda Group of Institutions, Greater Noida, HCL, ERA, Ansal Housing, India Habitat Center and many more.

At Jindal Mechno Bricks, we understand that architects and designers have design visions which sometimes require customized sizes, shapes, curves and colours. In past, we have worked closely with architects to understand their design requirements and match it with the scope of customization to deliver the best possible options. Clay is one such material which can be shaped in numerous ways and we love taking challenges to experiment with the scope of customization.

Brick making process involves mixing of different types of clays in proportionate amounts at fixed moisture contents before extrusion or pressing can be done. The real challenge here is the main ingredient, clay itself which is a constant variable. Thereafter, drying and firing durations as well as temperatures are controlled to be able to make the perfect brick. Brick making is a skill that is perfected through generations. At Jindal Mechno Bricks, with the third generation working in the brick making business now, we have always focused upon customer satisfaction as the key to business success.

Considering the tedious process that clay has to go through to become a brick, it should never be plastered or painted. Therefore, we are dedicated to making bricks that are not only aesthetically beautiful but also capable of performing when left exposed on the building facades. Brick properties like compressive strength, water absorption, efflorescence and warpage are carefully monitored to deliver the best quality. Brick and related products never fade, peel or rot. Therefore, you will never need to paint and will hardly ever have to clean. Compare a brick home with others and soon you’ll realize how much money, effort and time brick home owners save. So, use brick and just keep all your time for more important things in life!

200 Tonnes per day

of firing capacity

6 Lakh sq. feet

of manufacturing facility

25 years

of experience

Ethics

- Use world class technologies to produce superior quality products

- Have stringent quality checks before dispatch

- Testing the performance of all the products, by reputed labs

Our Product's Strength

Zero Maintenance

Bricks and related products never fade, peel or rot. Therefore, you will never need to paint and will hardly ever have to clean.

Timeless beauty

Bricks products never age. They last through centuries like the aqueducts in Rome. Brick is the material of past present & future

Evergreen Colours

Bricks and related products never fade, peel or rot. Therefore, you will never need to paint and will hardly ever have to clean.

Energy Saving

Products like 8-hole brick, multi hole brick and hollow block provide excelent thermal and sound insulation. This means lesser bills of A/C in summers and heater in winters.