Face Bricks

Home » Face Bricks

Explore Our

Best Quality Clay Face Bricks

Face brick is the term used for the bricks that are needed not just for the structure but also for aesthetics, energy efficiency, and value. These are the bricks that are intended to be left exposed on the walls of the building without any plaster or paint. These are lightweight, high quality bricks, high-strength, and differently coloured bricks that are fired at a really high temperature.

Brick / Tile Calculator

| 4 Inch | 9 Inch | |

|---|---|---|

| Total Required | 0 | 0 |

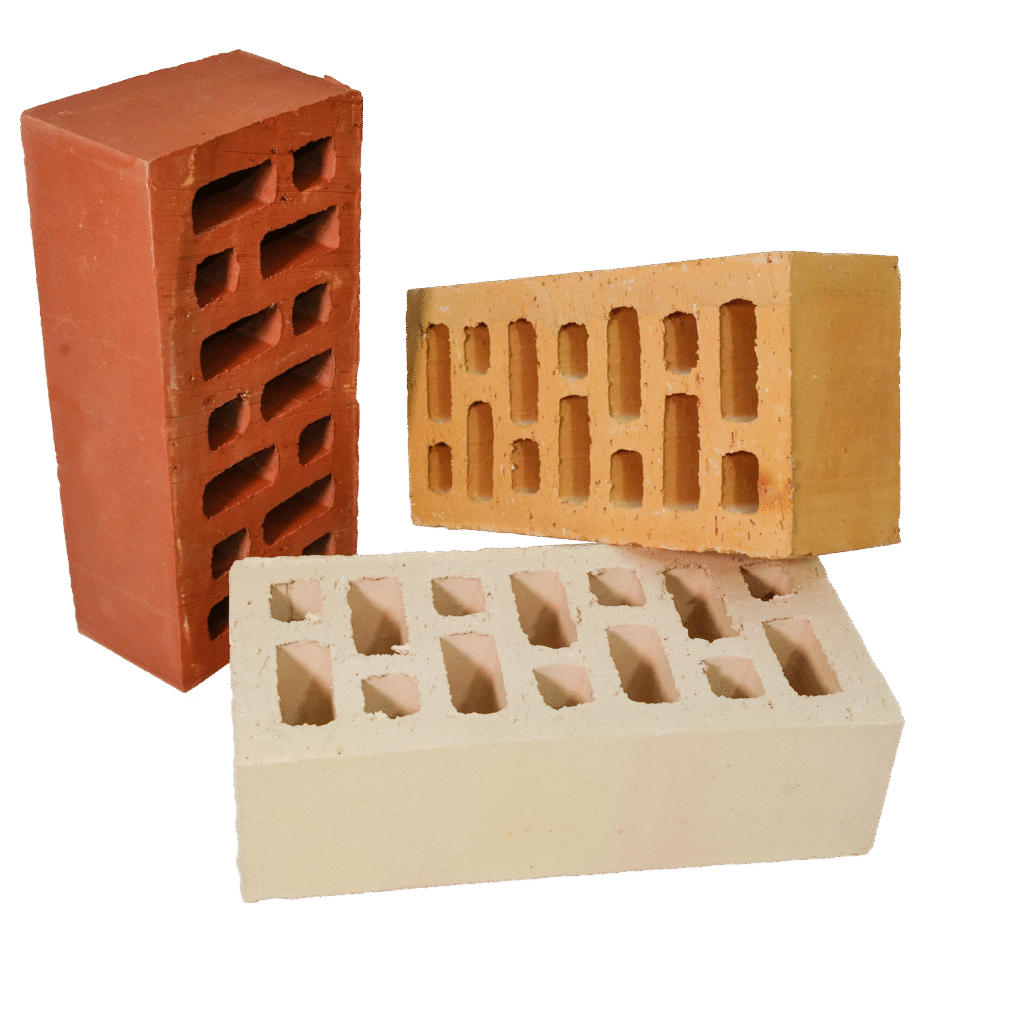

Facing Brick Dimensions and Shapes

Multi Hole Brick

It is a light-weight brick with excellent thermal and sound insulation. The edges and corners of the brick are a little rounded, making it ideal for structures with classic look. Available in various colours and configurations.

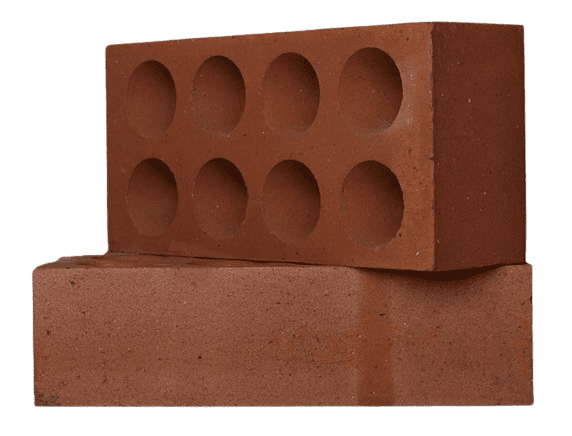

8 Hole Brick

The 8 conical holes in the brick, trap air inside and provide better thermal insulation than ordinary brick. Moreover, pressed bricks have sharp edges and corners, making it ideal for buildings with modern or contemporary architecture.

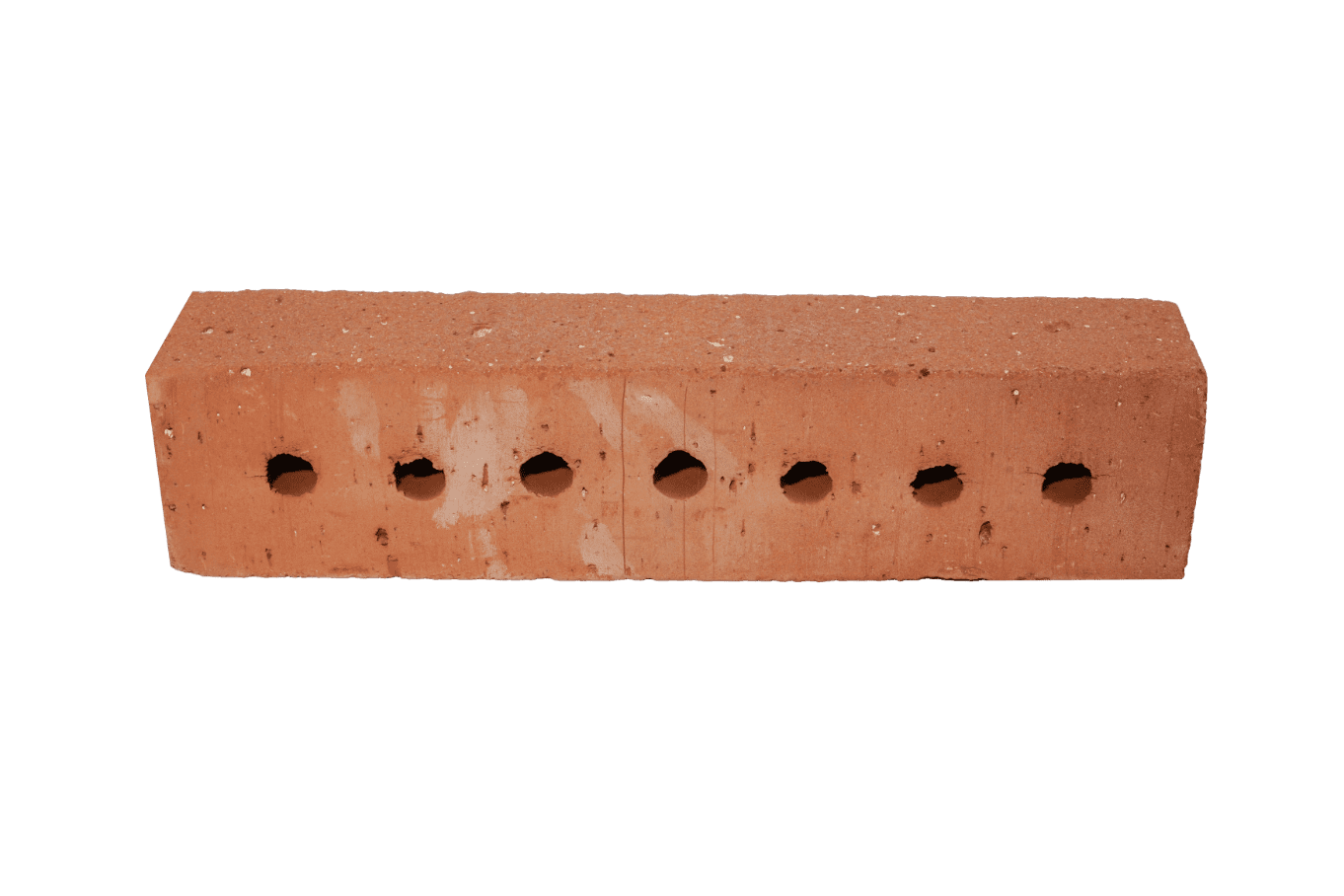

7 Hole Brick

Our 7-hole pressed brick combines maximum strength with refined design. Featuring sharp edges and smooth corners, it ensures structural reliability while enhancing the aesthetics of modern facades and contemporary spaces.

3 Hole Brick

The 3-hole pressed brick is a premium addition to our product range. Designed in our largest size, it delivers exceptional compressive strength. With sharp edges and precise corners, it is ideally suited for projects that demand a clean, modern, and contemporary look.

2 Hole Brick

The 2-hole pressed brick is the latest addition to our range of brick. It is our largest size brick with very high compressive strength. Pressed bricks have sharp edges and corners, making them ideal for buildings with modern or contemporary architecture.

Facing Brick Features and Benefits

Our brick performs well when left exposed.

Exposed bricks properties like compressive strength, water absorption, efflorescence, and warpage are carefully monitored to deliver the best qualities that make our brick capable of performing better when left exposed.

Required Less Maintenance

Brick and related products never fade, peel or rot. Therefore, you will never need to paint and will hardly ever have to clean. Compare a brick home with others, and soon you’ll realise how much money, effort, and time brick homeowners save.

No Color Pigments

The coloured bricks and related products are achieved by mixing clays (sourced from various parts of the country) and firing the resulting mixture at a certain temperature. There are no artificial colours or pigments added to get the required colours.

Time Saving

Our pressed bricks need not be plastered after installation. They can be left exposed, saving not only plaster, labour, paint costs but also time.

Timeless Beauty

Coloured bricks products never age. They last through centuries, like the trenches in Rome. Brick is the material of the past, the present & future, preferred because of its timeless beauty.

Modularity

The modular size of brick offers endless design options. You can use these high quality bricks anywhere and give your walls a classic look and feel.

SUPERIORITY

Why Choose Us for Face Bricks in India

Quality Assurance

Jindal Mechno Bricks is known for its commitment to delivering high-quality face bricks. Our products undergo strict testing and quality checks to ensure consistency and durability.

Technological Advancements

The company keeps up with technological advancements, incorporating modern manufacturing techniques to enhance the quality and aesthetics of its lightweight bricks.

Wide Range of Options

We offer a wide range of exposed bricks in various colours, textures, and sizes, allowing customers to find the perfect fit for their construction and design requirements.

Strong and Durable

Jindal Mechno Bricks' face bricks are designed to withstand the test of time, ensuring long-lasting performance and minimal maintenance.

Experienced Manufacturer

With years of experience in the brick manufacturing industry, we have developed expertise in producing high quality bricks that meet the industry's highest standards.

Customer Support

We provide excellent customer support, assisting clients in choosing the right face bricks for their projects and offering guidance throughout the process.

Jindal Mechno Bricks Best Building Materials Provider in India

Jindal Mechno Bricks stands as the famous building materials provider in India, setting the standard for quality and trustworthiness in the industry. With a wide array of top-notch products, including face bricks, extruded bricks, and exposed bricks, their offerings cater to diverse construction needs.

Backed by years of experience, the company ensures each material meets stringent quality checks, guaranteeing durability and performance. From sustainable manufacturing practices to a strong commitment to customer satisfaction, Jindal Mechno Bricks is the preferred choice for architects, builders, and developers nationwide.

| Benefit | Description |

|---|---|

| Enhanced Aesthetics | Face bricks add a timeless and attractive appeal to buildings, elevating their visual appeal with a variety of colours, textures, and patterns. |

| Durability | These bricks are highly durable, capable of withstanding harsh weather conditions, UV rays, and wear, ensuring a long-lasting and low-maintenance exterior. |

| Insulation Properties | Face bricks offer excellent thermal insulation, regulating interior temperatures and reducing the need for additional insulation materials. |

| Sound Insulation | They provide soundproofing benefits, reducing noise transmission and enhancing acoustic comfort inside the building. |

| Fire Resistance | Face bricks are naturally fire-resistant, offering added safety and protection to the structure and its occupants. |

| Environmentally Friendly | Made from natural clay and minerals, face bricks are eco-friendly, as they are recyclable and do not emit harmful substances. |

What is face vs common brick?

- Face bricks are specifically designed to be visible on the exterior surface of a building due to their attractive appearance. They have a finished surface on one or both sides and are used for aesthetic purposes. On the other hand, common bricks are more basic and are typically used for structural purposes, often hidden under plaster or other materials.

How are face bricks made?

- Face bricks are made by mixing clay with water, shaping it into bricks, drying them, and then firing them in a kiln (thermally insulated chamber) to make them strong. After cooling, the bricks undergo a quality check before being used in construction.

Why is it called face brick?

- Face bricks are called so because they are meant to be the visible face of a wall. They are used for the exterior surfaces of buildings to provide an attractive and finished appearance. The term “face” refers to the side of the brick that is exposed when the wall is constructed.

Are face bricks waterproof?

- Face bricks are not naturally waterproof; they are absorbent and soak some water. However, they offer good resistance to water penetration when properly installed with an appropriate water-repellent mortar and a weather-resistant backing material. Additional measures like sealing the joints with a suitable sealant can be taken to enhance water resistance.